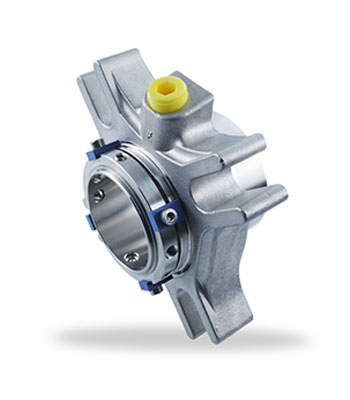

H74-D Mechanical seals for pumps

$0.00

Additional information

| SEAL FACE | Silicon carbide (Q1, Q2), Carbon graphite antimony impregnated (A), Aluminium oxide (V), Special cast CrMo steel (S) |

|---|---|

| SEAT G9 | Carbon graphite antimony, impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (Q1*,Q2*) |

| SECONDARY SEALS | EPDM (E), NBR (P), |

| SPRINGS | CrNiMo steel (G) |

| METAL PARTS | CrNiMo steel (G), Duplex (G1) |

Description

Features

- For stepped shafts

- Dual seal

- Balanced

- Rotating multiple springs

- Independent of direction of rotation

- Seal concept based on the H7 range

- *Variant with pumping screw available

- (H74F-D)

Advantages

*Efficient stock keeping due to easily interchangeable faces

- Extended selection of materials

- Flexibility in torque transmissions-

- Insensitive to low solids contents

*EN 12756 (For connection dimensions d1 up to 100 mm (3.94″)) (G16)

Shaft diameter:

d1 = 14 … 200 mm (0.55″ … 7.87″)

Pressure:

p1 = 80 bar (1,160 PSI) for d1 = 14 … 100mm,

p1 = 25 bar (363 PSI) for d1 = 100 … 200mm,

p1 = 16 bar (232 PSI) for d1 > 200 mm

Temperature:

t = -50 °C … 220 °C (-58 °F … 428 °F)

Sliding velocity: vg = 20 m/s (66 ft/s)

Axial movement:

d1 up to 100 mm: ± 0.5 mm

d1 from 100 mm: ± 2.0 mm

Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Power plant technology

- Pulp and paper industry

- Low solids content and low abrasive

- Toxic and hazardous media

- Media with poor lubrication properties

- Adhesives

- Chemical standard pumps

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.